Mince pies and turkey

are all well and good, but it's the salty tang of Stilton that is the

true taste of Christmas for cheese lovers.

Britain's most famous blue

is the perfect partner for port or Christmas cake, but there's

another reason why it's the cheese of choice over the festive period.

Stilton is in its absolute prime in December because it has been made

with rich summer milk.

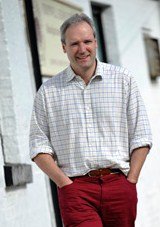

Robin Skailes at

Cropwell Bishop Creamery in Nottinghamshire, whose family have been

making Stilton for over 60 years, explains: “The Stilton you eat at

Christmas has been maturing for at least 10 weeks, so was actually

made in September. That's when the cows have been feeding on the lush

pastures of the Peak District all summer, so they are producing the

ultimate milk for making a soft blue cheese just in time for

Christmas.”

Robin and his cousin

Ben Skailes are the third generation of the family to Stilton. Like

their grandfather, Frank, who bought the company in 1949, they are

sticklers for tradition, especially when it comes to choosing a

perfect cheese for their own Christmas dinner.

“There's always a

huge piece of Stilton on the table in the Skailes household at

Christmas,” say Skailes. “Each year our head grader puts aside a

few really good cheeses and my father makes a special visit to the

dairy to personally pick the best one for the family. It's a long

family tradition.”

“There's always a

huge piece of Stilton on the table in the Skailes household at

Christmas,” say Skailes. “Each year our head grader puts aside a

few really good cheeses and my father makes a special visit to the

dairy to personally pick the best one for the family. It's a long

family tradition.”

Protected by EU laws in

the same way as Parmesan or Champagne, Stilton can only be made in

the three counties of Nottinghamshire, Leicestershire and Derbyshire

using traditional recipes. The strict rules mean there are currently

only five Stilton producers, some of which are large industrial

manufacturers, but not much has changed at Cropwell Bishop since

Skailes' grandfather took over.

|

| Robin Skailes |

Milk is sourced from

small family farms, while almost all of the work is still done by

hand from cutting the curds to filling and turning the moulds to

ensure the cheeses form evenly inside - an impressive feat when you

consider that 500 of the 7.5kg Stilton 'rounds' are made every day.

Strong arms are

required for this weighty job, says Skailes, but a light touch is all

important when the cheeses are removed from their hoops. A team of

nimble-fingered ladies 'rub up' the young rounds using a knife and a

flick of the wrist to smooth the sides and create an air-tight seal.

No comments:

Post a comment